Tesla Shooting Brake: Niels Van Roij

Vehicle Badge Design For The Tesla Shooting Brake Conversion Taken From The Designers (Niels Van Roij) Website.

As our Tesla Model S based Shooting Brake conversion is made entirely by hand of the best materials, we did not want any plastic to be used as a base for our badge nor any details of it. In the search for the right party to manufacture our design, House of Logos stood out. They only make items in metals and by hand.

As our Tesla Model S based Shooting Brake conversion is made entirely by hand of the best materials, we did not want any plastic to be used as a base for our badge nor any details of it. In the search for the right party to manufacture our design, House of Logos stood out. They only make items in metals and by hand.

Metal looks and feels better compared to plastic and gives a far superior finish. As House Of Logos is dealing with OEM companies, the quality is outstanding. They have tested their metal badges for UV, discolouration, road salt, corrosion and so forth.

Metal looks and feels better compared to plastic and gives a far superior finish. As House Of Logos is dealing with OEM companies, the quality is outstanding. They have tested their metal badges for UV, discolouration, road salt, corrosion and so forth.

We had quite a wish list and House of Logos assisted and advised us. They took the time for lengthy conversations over many months to execute our badge design and its production.

Because of the very sharp edges we required, stamping our badges in a regular fashion was not a possibility. In that case only a rounded edge could be incorporated due to the technical restriction of the stamping procedure.  Our badge design required a 90 degree top and a 45 degree faceted corner. Because of this, they had to be cast in zinc alloy rather than stamped in copper and a special 3D mold to cast the badges was made. This tool was used to injection mold the base metal and create the cut-out look we designed.

Our badge design required a 90 degree top and a 45 degree faceted corner. Because of this, they had to be cast in zinc alloy rather than stamped in copper and a special 3D mold to cast the badges was made. This tool was used to injection mold the base metal and create the cut-out look we designed.

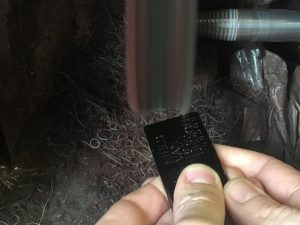

We decided to go for a black nickel plating (similar to black chrome) for the metal base of the badge. To give the right perceived quality, the logo had to be recessed and filled with white enamel.

The logos were buffed by hand to make sure any small blemishes or imperfections would be removed, ensuring a nice even surface. Following that procedure, our badges went for plating. In our particular case, a black nickel base finish was required. The black nickel showcases the quality of the base metal material beautifully and depending on the angle, appears to be either fully black or chromed. The black chrome colour refers to the quality of the coach-building process.

In the final major stage, enamel colouring is added by hand to the recessed areas. For our badge, white enamel was chosen to be inserted. The enamel is the left to dry and set overnight, ready to be placed on the Tesla Shooting Brake.